- More than $1 billion investment to retool MAP, ELP and AEP.

- 100% recycling of aluminum scrap from the megacasting process at AEP.

- The longest Automated Guided Vehicle (AGV) line in Honda’s history for battery pack assembly at MAP.

Driving Progress

through innovation

Honda's EV Hub represents a transformative shift in how we build vehicles for the future. Through a more than $1 billion investment, we transformed our Ohio operations and expanded our hybrid lines—Marysville Auto Plant (MAP), East Liberty Auto Plant (ELP) and Anna Engine Plant (AEP)—to flexibly produce ICE, hybrid and EV models on the same lines. From new EV battery pack assembly at MAP to megacasting battery cases at AEP, we are creating a cleaner, smarter and more human-friendly work environment designed to meet the demands of the next generation of Honda and Acura vehicles.

What Is

the EV Hub?

One Vision. One Purpose. One Hub.

The Honda EV Hub is the heart of our flexible manufacturing strategy in North America. By locating our manufacturing and battery operations in close proximity to each other, we are creating a unified ecosystem to support next-generation EV production—starting with the all-new Acura RSX SUV, followed by models based on the Honda 0 Series.

Key Features

Partnerships

Integration with L-H Battery Company, a $3.5 billion JV with LG Energy Solution.

Hubs

Annual capacity of approximately 40 GWh.

Associates

Honda has reimagined manufacturing to create a work environment that is more human-friendly.

New Equipment

Honda is using processes like High-Pressure Die Casting and Friction Stir Welding in the mass production environment for the first time.

Energy Efficient

New high-efficiency equipment, including HVAC and melt furnaces that reduce CO2 emissions. Photogrammetry and friction stir welding for precise, energy-efficient quality checks.

Photogrammetry

To quickly and accurately visually analyze the quality of each battery case, AEP will employ a new multi-camera machine in two locations to achieve 100% quality confirmation.

Powered

by People

Driven by Our Associates

Our associates are at the heart of the EV Hub transformation. From hands-on training in new EV technologies to upskilling for quality assurance in software-defined vehicles, Honda associates continue to lead the way. With reimagined workspaces, new roles and expanded quality departments, the EV Hub is built as much for our associates as it is for the vehicles they create.

Designed for Flexibility and Sustainability

Built for Tomorrow

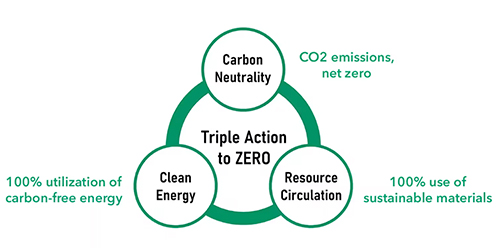

The EV Hub is built with the future in mind. Each Honda facility has been reconfigured to enable flexible production and support our sustainable goals: carbon neutrality, clean energy and resource circulation.